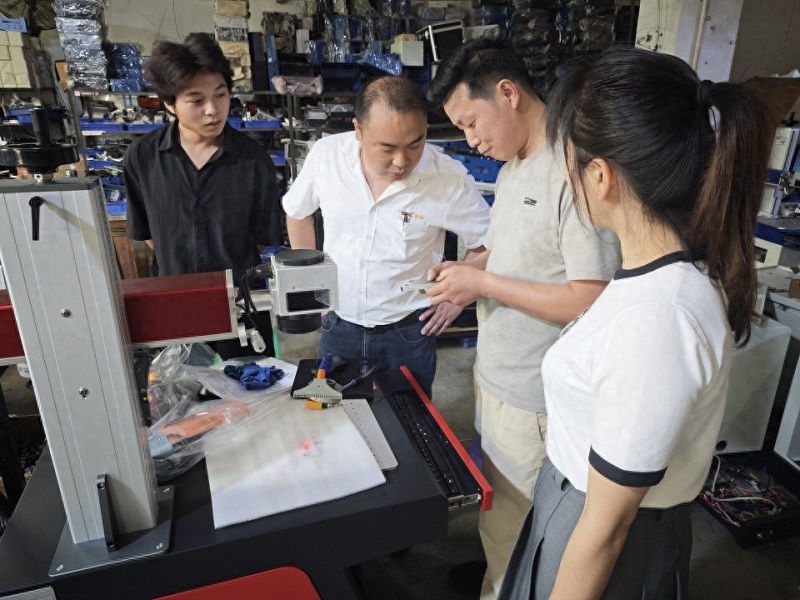

On April 19, 2025, Chongqing Chuke Intelligent Machinery Equipment Co., Ltd. (hereinafter referred to as "Chuke Intelligent") ushered in an important moment-a Volkswagen auto parts supplier customer visited the factory and witnessed the process effect of the 300W

Laser Marking Machine deeply engraving the Volkswagen logo. He highly praised the quality of the sample and signed the annual cooperation order on the spot. This cooperation marks that Chuke Intelligent's laser marking technology in the field of automobile manufacturing has once again been recognized by international first-line brands.

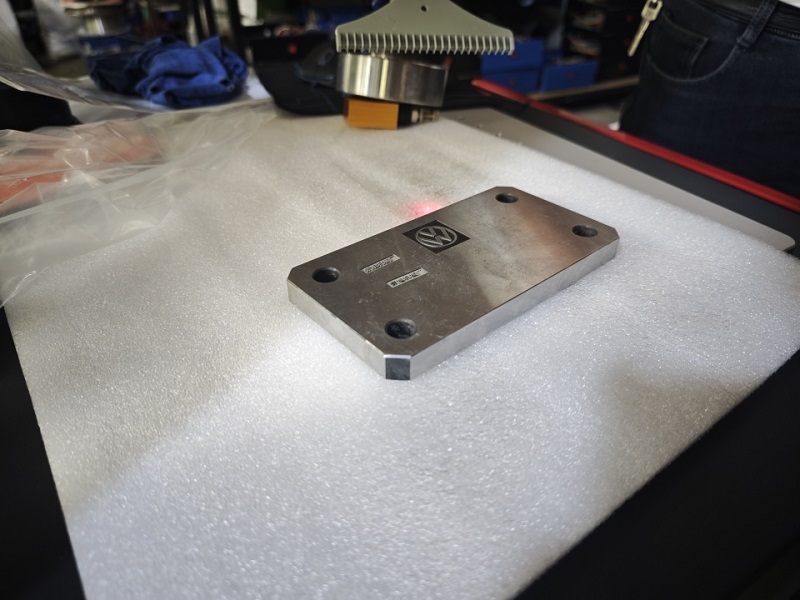

This time, the customer required the deep engraving of the Volkswagen brand logo on metal materials, and put forward strict standards for marking accuracy, depth and edge sharpness. The Chuke Intelligent technical team selected the self-developed 300W

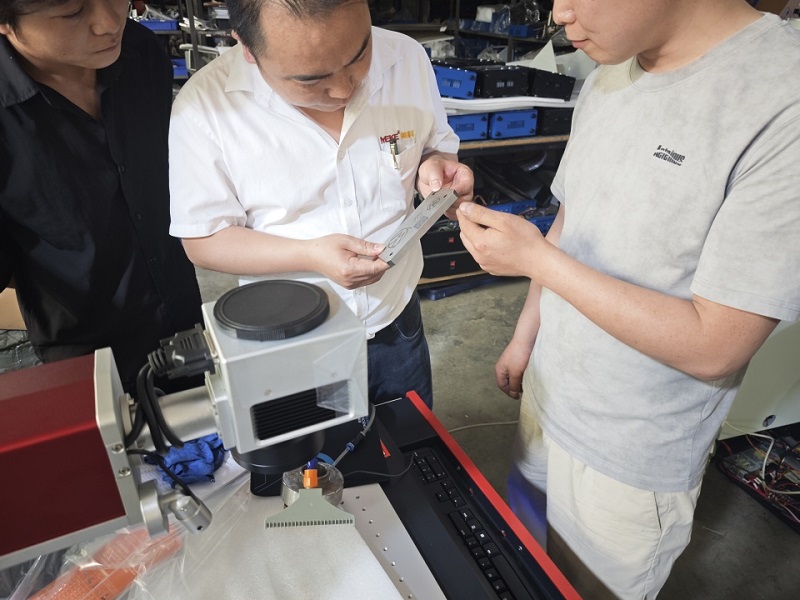

Fiber Laser Marking Machine, and achieved a beam quality close to the diffraction limit (M2<1.1) through high-power pumping technology and all-fiber structure, ensuring clear logo lines and uniform depth. The test results show that the laser energy density can be accurately controlled to an error of 0.05 mm, meeting the automotive industry's anti-counterfeiting and traceability needs for parts identification.

During the on-site acceptance, the customer representative said: "The scanning success rate of the QR code engraved on the metal surface by Chuke Intelligent's equipment is 100%, and there are no appearance defects caused by the heat-affected zone, which fully complies with Volkswagen's global supply chain standards." This evaluation directly led to the signing of an annual framework agreement between the two parties, covering the identification processing business of core products such as automotive shock absorber springs and engine parts.

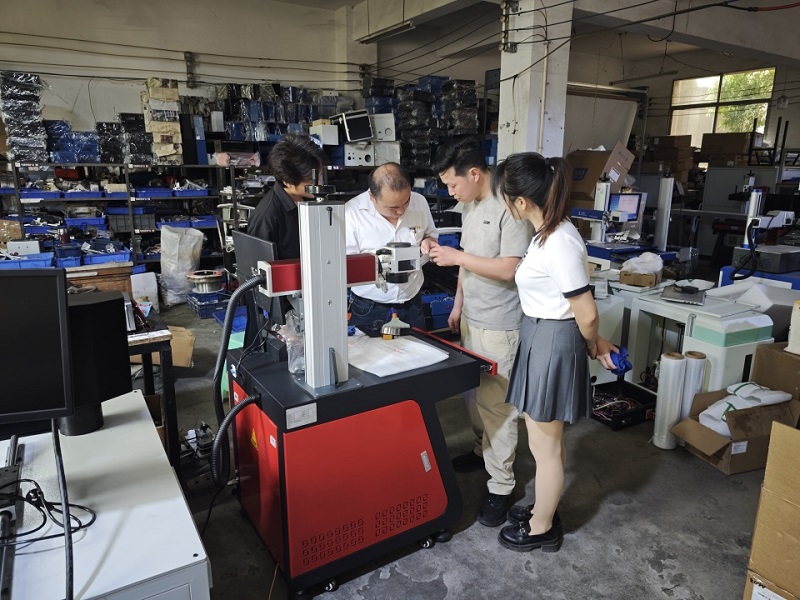

In this cooperation, Chuke Intelligent's technical advantages are not only reflected in the stability of the 300W fiber laser

Marking Machine, but also in its ability to integrate laser solutions for different materials. For example, in response to the customer's previous difficulties in marking the arc surface of the shock absorber spring, Chuke Intelligent recommended a

UV Laser Marking Machine, which uses cold processing characteristics to avoid thermal deformation, improves the sharpness of the QR code edge by 30%, and increases the scanning success rate from the industry average of 85% to 99.8%. This technical solution ultimately helped customers achieve a 40% increase in production efficiency and an increase in the yield rate from 75% to 98%.

This cooperation is not the first time that Chuke Intelligent has been recognized by the automotive industry. Previously, the company has delivered a customized

Uv Laser Marking machine to a large automotive shock absorber spring manufacturer in Turkey to solve the pain point of low success rate of QR code scanning. The springs produced by this customer need to be marked after polishing and electroplating. Traditional fiber lasers are prone to poor appearance due to uneven heat, while Chuke Intelligent's UV laser solution perfectly avoids this problem and helps customers achieve excellent comprehensive quality management.

At present, Chuke Intelligent's products have been exported to more than 100 countries in Europe, America, Southeast Asia, etc., and have successfully entered high-end manufacturing fields such as automobile manufacturing, aerospace, and electronics. Its

Laser Welding Machine can achieve efficient stamping 80 times per minute in the production of new energy vehicle battery shells, with an error control within 0.05 mm, significantly improving production efficiency and product quality.

In the face of the global trend of intelligent transformation of manufacturing, Chuke Intelligent continues to increase its R&D investment to promote the deep integration of laser technology with artificial intelligence and the Internet of Things. The company plans to release a new generation of intelligent laser marking system at the 2025 Canton Fair, integrating machine vision and AI algorithms to achieve real-time quality inspection and adaptive adjustment of process parameters. Xiao Renmin said: "In the future, we will take 'innovation-led, quality excellence' as our development concept, provide more intelligent and efficient laser equipment solutions to global customers, and promote the high-quality development of the manufacturing industry."