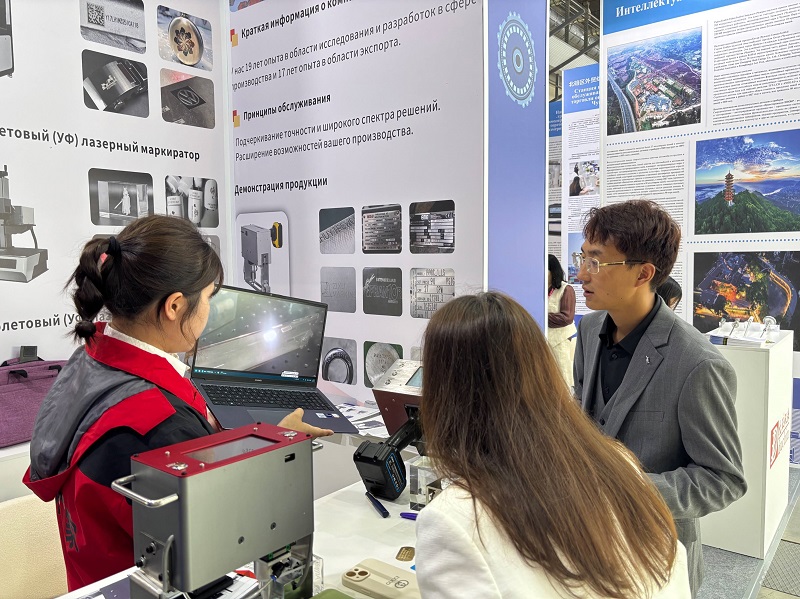

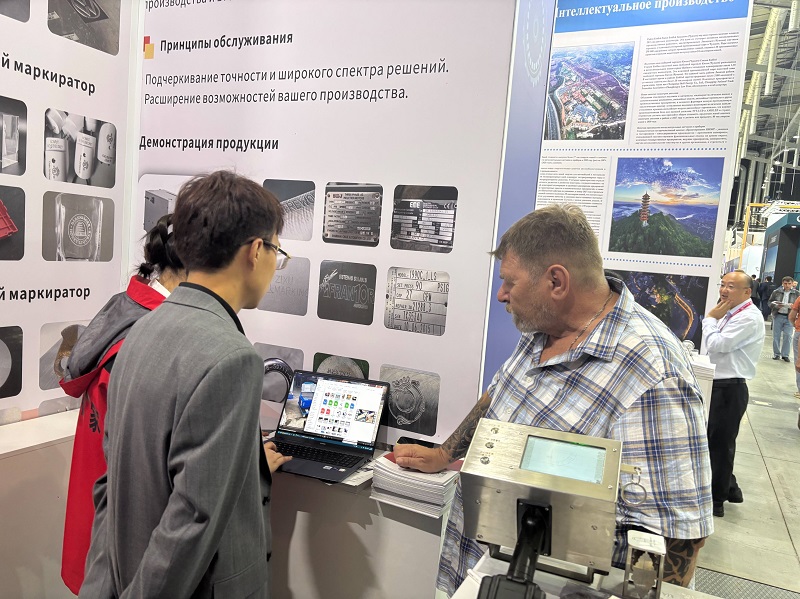

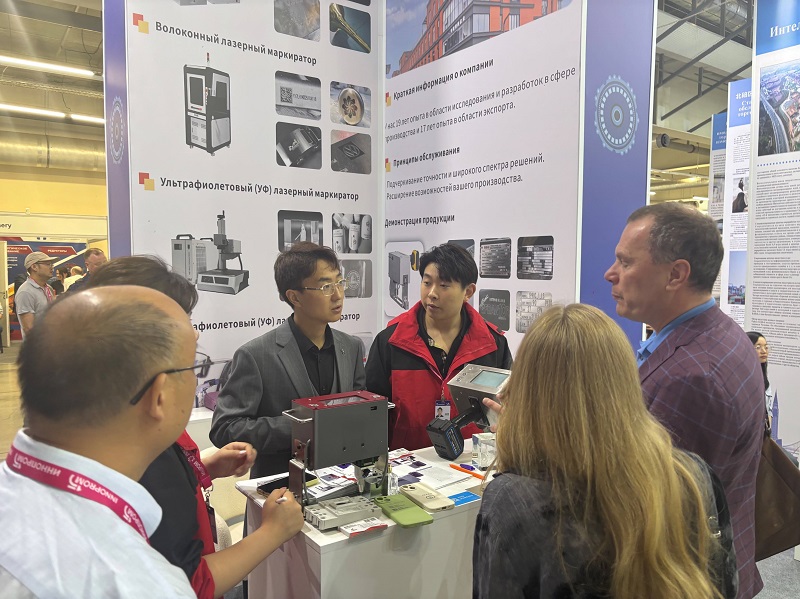

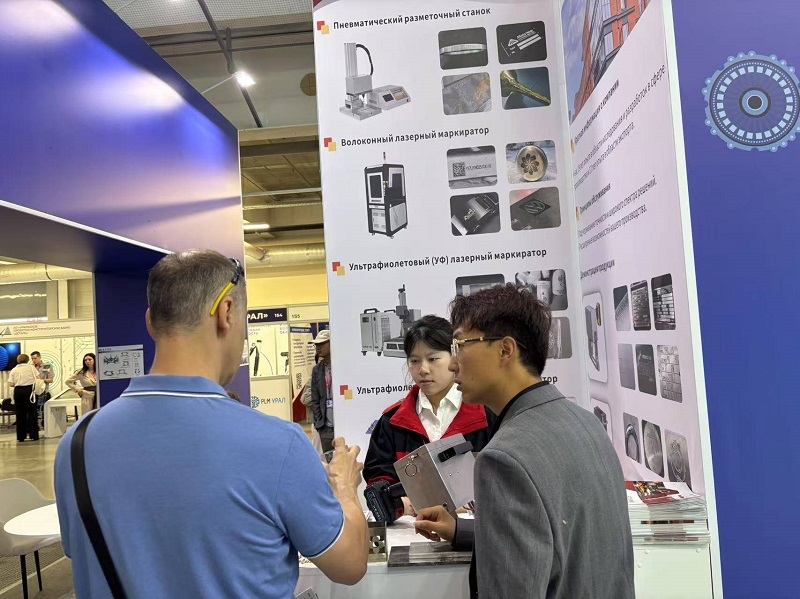

On July 9, 2025, on the third day of the 2025 Russian International Industrial Trade Fair (INNOPROM 2025), Chongqing Chuke Intelligent Machinery Equipment Co., Ltd. (hereinafter referred to as "Chuke Intelligent") became the core focus of the exhibition with its high-precision

Laser Marking Machine, intelligent

Laser Cleaning Machine and automated laser welding solutions. The booth was packed with people for three consecutive days, attracting in-depth reports from multiple Russian TV stations and mainstream media such as paper media, and attracted great attention from global industrial buyers.

At the exhibition site, the

Fiber Laser Marking Machine exhibited by Chuke Intelligent became the "preferred solution" for Russian auto parts companies with its 0.01 mm accuracy and real-time update function of dynamic data. The equipment can realize permanent QR code marking on metal surfaces, is wear-resistant and high-temperature resistant, and perfectly replaces traditional ink processes. After on-site testing, the technical director of a Russian automobile group said: "The equipment can still operate stably in an extremely cold environment of -40℃, and the marking efficiency has increased by 3 times, which has completely solved the problem of our anti-counterfeiting traceability and automated production line docking."

In response to the cleaning needs of the metal processing industry, the Chuke Intelligent 200W intelligent laser

Cleaning Machine has attracted attention with its non-contact and no wastewater discharge characteristics. The equipment quickly removes oxides and coatings on the metal surface through laser beams, and its efficiency is 5 times higher than that of traditional chemical cleaning. A representative of a mining company in Siberia said: "The extremely cold climate causes chemical cleaning agents to freeze easily, and Chuke Intelligent's

Laser Cleaning machine can save us 2 million rubles in environmental protection treatment costs each year."

On the first day of the exhibition, Chuke Intelligent reached a preliminary cooperation agreement with several Russian automobile manufacturers to customize laser welding automated production lines for them. The solution integrates robot welding, visual inspection and data traceability systems to achieve 80 efficient stampings per minute, and the welding error is controlled within 0.05 mm, which is 40% higher than the traditional process accuracy. A representative of the Russian Industrial Association commented: "Chinese equipment has significant advantages in cost-effectiveness and customized services. Chuke Intelligent's multi-language operating system and localized technical support help us seamlessly connect to automated production lines."

Tao Yuanyuan, the person in charge of Chuke Intelligent's exhibition, said in an interview with several Russian TV stations: "Chongqing has a trillion-level automobile and motorcycle parts industry cluster, and Russia has a strong industrial base and mineral resources. We are using laser technology as a link to promote the deep integration of "Chongqing Smart Manufacturing" and Russian manufacturing."

During the exhibition, Chuke Intelligent announced that it will set up its first overseas service center in Russia, equipped with a team of technical engineers and spare parts warehouses, and provide 72-hour emergency response services. Tao Yuanyuan revealed: "We plan to build a joint laboratory with Russian scientific research institutions to develop special laser equipment for polar equipment, heavy machinery and other scenarios, and further expand the boundaries of Sino-Russian technical cooperation."