In modern industrial production, the improvement of production efficiency is crucial to the development of enterprises. As an efficient and precise processing equipment,

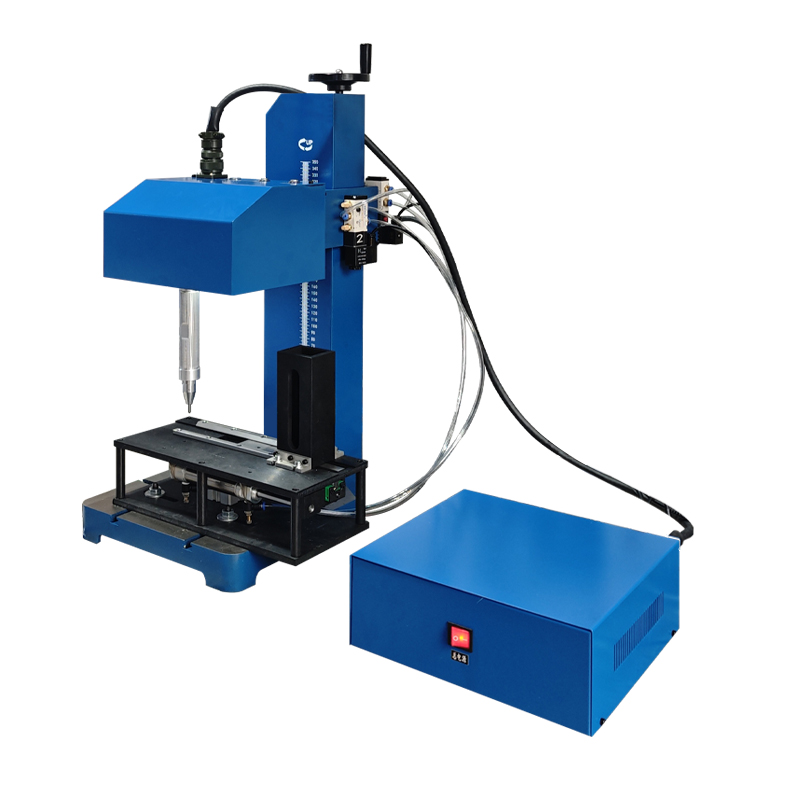

Pneumatic Dot Peen Marking Machine have been widely used.

In order to better grasp the processing process of

Dot Peen And Scribe Marking and improve production efficiency, we need to understand the following key points.

Before using Pneumatic

Dot Peen Marking Machine for processing, we must first determine the appropriate materials and process parameters. Different materials react differently to lasers, so we need to adjust according to actual conditions.

In addition, the reasonable selection of process parameters, such as laser power, frequency, speed, etc., is crucial to ensure the processing effect.

Designing a reasonable processing layout can effectively improve production efficiency. When processing Dot Peen And Scribe Marking, we can reasonably arrange the processing sequence and processing path according to product characteristics and processing requirements, minimize the material transportation and clamping time, and improve production efficiency.